A Biased View of Warehousing Storage

Wiki Article

Warehousing Storage - Questions

Table of ContentsGet This Report on Warehousing StorageMore About Warehousing StorageSome Known Details About Warehousing Storage The Best Strategy To Use For Warehousing Storage

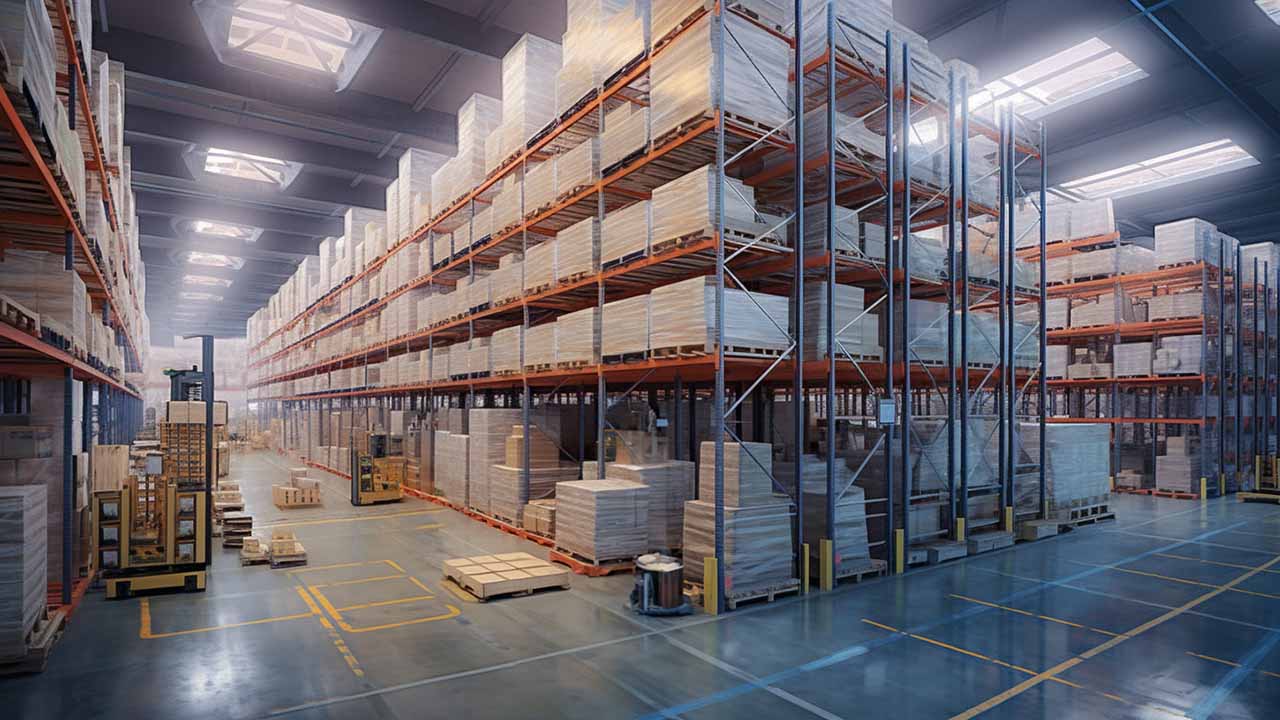

Warehousing refers to keeping a product that had actually been produced in mass up until there is demand and market or it. Storehouses, on the various other hand, are dedicated storage areas where these commodities are positioned till consumers require them. Because of recent developments in modern technology, warehousing for supermarket is ending up being simpler and simpler.Here are some of the methods which warehousing for grocery store advantages company proprietors and consumers. One incredible benefit of keeping food in a storage facility is that it makes it feasible for the producer of these assets to satisfy consumers' demands, despite exactly how immediate or huge the order is.

Warehousing for grocery store helps you protect your goods from components of weather condition such as rain and intense heat from the sun, which can damage your items if not resolved. If your food comes right into contact with water, it's just a matter of time before everything starts spoiling.

Not known Facts About Warehousing Storage

Operating a storage facility would certainly require you to build one, first of all, then equip it with the required tools and machinery. You 'd also have actually to employ specialized labor to deal with such storage facility activities as packaging and blending.

Although it is the business that profits the most from warehousing, there are some benefits that splash over onto the consumer. Warehousing makes it feasible for them to get the assets whenever the need emerges, regardless of necessity or the volume they would certainly like to acquire. Some sellers permit consumers to buy directly from the storehouse, especially if it is a mass purchase, and this saves them from needing to drive down to the manufacturer's farm or greenhouse to make orders.

Everything about Warehousing Storage

An additional advantage of warehousing is saving long-shelf-life goods in a safe, lucrative manner. This lowers time spent on getting at your facility and enables both you and your staff to focus on satisfaction, customer solution, and various other storage facility services.

There are several important concepts to maintain in mind when creating a stockroom logistics and circulation method. That indicates that their stock turnover price is reduced. There are multiple principles of warehousing that allow storage facilities to run efficiently and supply terrific outcomes for clients.

The Only Guide to Warehousing Storage

Warehouse supply administration software or an ERP from this listing of ERP systems makes it also simpler to track just how much is kept and where (warehousing storage). Attaining a low item touch frequency is likewise indispensable to accuracy. Greater than 60% of customers agree to pay more for same-day distribution. These stats reveal quick delivery and distribution is a modern necessity. Your business needs to provide it any place possible. You can likewise enhance your delivery speed with the assistance of a stockroom administration system. Stockroom logistics involve a great deal. If you are intending on going the in-house fulfillment path, after that you need to know exactly how to take care of order fulfillment. It doesn't matter whether you're offering online or in individual (or both); each order calls for attention and needs to be refined appropriately. Order fulfillment consists of picking the ideal things at the right time and packing them for shipment. A lot of stockroom team use a thermal label printer, which is fast and inexpensive. Obtaining products to clients is the final step. Depending on your target market, you might be shipping to retail stores, straight to consumers, or both. You can use your own transportation if you have it, however a lot of organizations transform to third-party logistics firms. Usage repackaging as a supply decrease technique. Lower storage space prices by utilizing a supply stockroom. Be prepared to take care of raised sales via bigger storage space capability. Be prepared to manage enhanced sales with making use of numerous stockrooms with stock transfers in between them. Storehouse and warehousing share the exact same root word, however they aren't necessarily the same. The objective with any type of business is to be lucrative at scale. Efficient warehousing permits you to elevate your costs without way too much of your costs lowering your revenues. This is challenging in physical product services, as there's always a cost tied to your sales, which is the cost of products internet sold. Stockrooms might have wheels, rails, or other automated equipment to move inventory. The products might initially be sorted right into various groups or pallets. It is after that manually or mechanically relocated to the storage racks and put. This might include the use forklifts,palletjacks, or various other equipment. Selecting includes the selection of products from the storage space area for loading into the last unit. Selecting might entail a pick-to-order or pick-to-stock inventory system. If a pick-to-order procedure is used, an order is put for every product. If a pick-to-stock system is made use of, stock is chosen from shelves just when it is marketed. After things are packed, they are by hand transferred to a shipping location, packed onto conveyor belts, or automated carts for delivery. Storage facilities frequently have details areas or devices for each of these activities. They additionally have specific areas for obtaining, storing, and shipping. Logistics is the process of purposefully planning and handling the circulation of goods from a point of origin to the point of intake. Warehousing is one part of logistics, and a very fundamental part. By their actual see it here nature, storage facilities are full of 10s of thousands, otherwise millions of dollars worth of products. All it takes is a few shady people hatching out a plan, sneaking in, and assisting themselves to the five-finger discount rate. If you do not have gain access to control systems and safety electronic cameras in place, your stockroom brings tremendous danger. Employees must be well accustomed to the tools they use everyday( for even more details, see what is a storage facility partner). You need to constantly give detailed training to each staff member for every item of tools they run. Mishaps commonly occur in a fraction of a second, especially with huge and hefty devices. When it concerns e, Commerce, selecting excellent warehousing is equally as essential as getting the right item. Your stockroom is basically the foundation of your e, Commerceorganization. It will certainly be accountable for storing, monitoring, and delivering your items. This might look like a great deal to believe concerning upfront, however trust us when we claim that these details are essential. What should you look for in a storehouse remedy? Anything that's mosting likely to be useful for your firm progressing. There are hop over to these guys many aspects to think about when spending in stockroom logistics, such as convenience of execution, scalability, and reporting abilities. Here are six questions to ask yourself: When you're creating your stock storage facility, start with a solitary thing on your shelves and job in an outward direction. But your customers desire to know all that, plus the price, the delivery times, and where the item is originating from. Basically, one process offers 2 masters: your internal requirements and your consumer's needs. The service you're thinking about might have inventory storehouse software program of its own. If you're starting out with a tidy slate, after that you'll require to discover a WMS that works for you. Obtaining your inventory data right into your WMS is only the beginning. You want to be able to draw that data out once againand use it for other objectives. That's where information interfaces been available in. What data interfaces does your WMS offer? Are any of them optional? If your WMS offers a conventional information user interface, like an API, after that you remain in luck. Data interfaces are the ports between your WMS and various other apps and services. They are the manner ins which information enters into and out of your WMS. A custom data interface for your WMS tells you that it's adaptable and versatile. Which's a good indication. Storage facility facilities are great. They are very organized places for inventory management. It likewise develops a chance for human mistake. The finest WMSs are incorporated with your other software. By doing this, you make use of one procedure for both purposes. You'll save on physical space. And you'll reduce the risk of human error. If your WMS can only take care of a handful of SKUs, that's a poor indicator. It should help every product in your supply storage facility, despite how much space you wind up making use of. It should grow with you. If you want to be able to keep a vast array of products, after that you desire to make certain your WMS can handle it. You additionally intend to ensure you canscale up as your company grows. You'll be persevered for the long run. You want to make certain your WMS integrates with your chosen delivery company. This is important if you wish to track your products through the whole supply chain. It's likewise helpful if you have a robust customer care team.Report this wiki page